Normal

Stuff

00. If you kill yourself, it is not my fault. :-)

01.

Place tire blocks in front of the front wheels.(Or behind if on a

decline.)

02. Jack up both rear wheels and place car on jack stands.

03.

Remove both of the rear wheels.

04. Disengage parking/emergency brake.

05.

Place car in neutral.

Halfshaft Removal

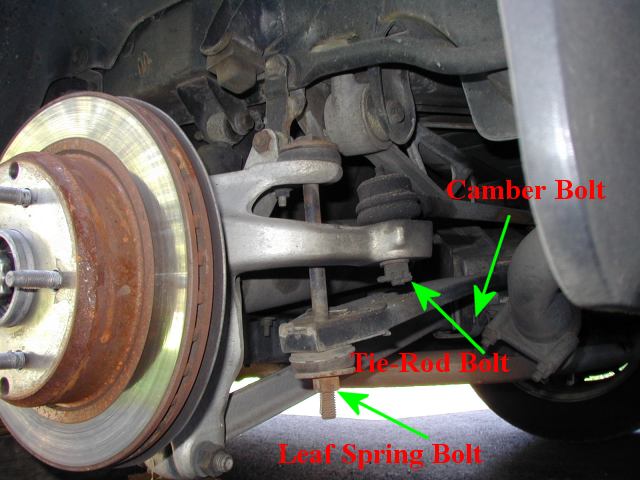

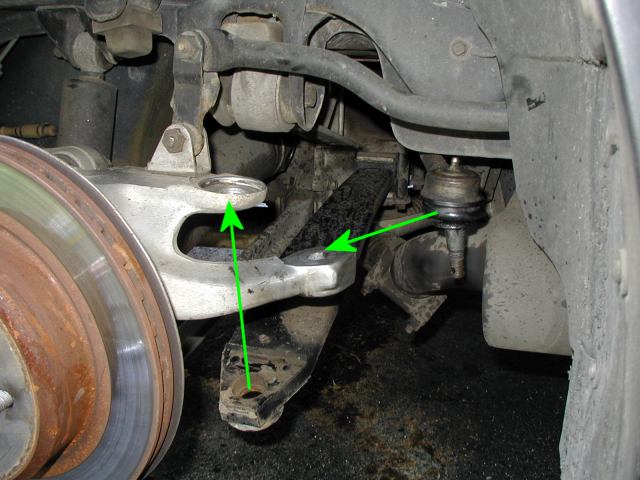

Well,

here is what we are going to remove....

06. Place a jack under the Leaf Spring on the side

you are working on.

07. Jack leaf spring up approximately 3

inches.

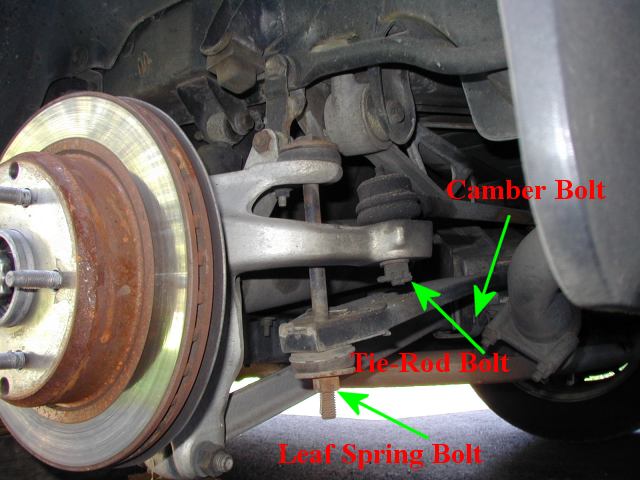

For reference, here are the 3 main pieces that are required to be

removed in order to pull the halfshaft.

08. Remove cotter pin from leave spring nut.

09.

Remove cotter pin from tie-rod nut.

10. Remove leaf spring nut.

First count the number of threads showing before

removal and note it, then you can install it to the correct ride height again.

You need a long socket on the bottom, and closed wrench on the top. Use WD-40

liberally.

11. Remove leaf spring bolt.

Use WD-40 liberally.

12.

Remove tie-rod nut. Use WD-40

liberally.

13. Seperate tie-rod from knuckle with a

suspension fork. Be careful not to split open the

rubber fitting.

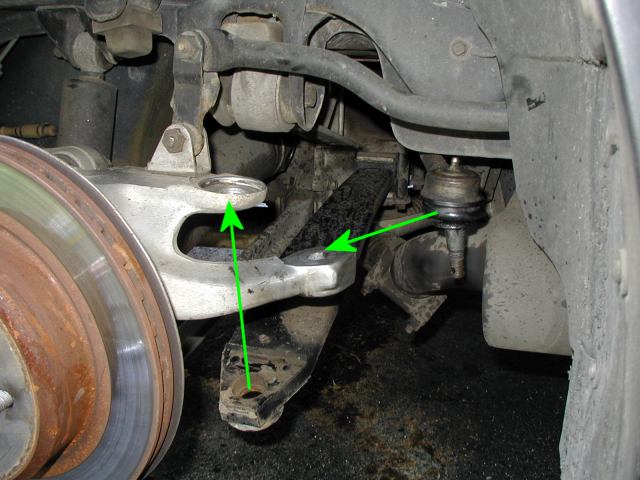

Progress so far.

14. Mark camber bolt for realignement after

reinstallation.

It is tough to see, but you need to scribe a line from

the bracket to the wheel on the camber bolt. When you reinstall this later you

have to line them up in order to maintain your car's alignment.

15. Remove camber bolt. Use

WD-40 liberally.

16. Gently hammer strut rod down and

out of its bracket.

Just knock it down out of it's bracket. Be careful

not to lose the two washers that will fall out with it on each side of the

bushing.

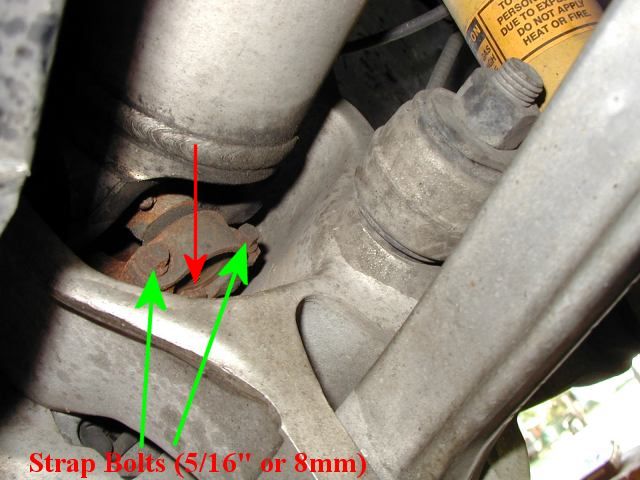

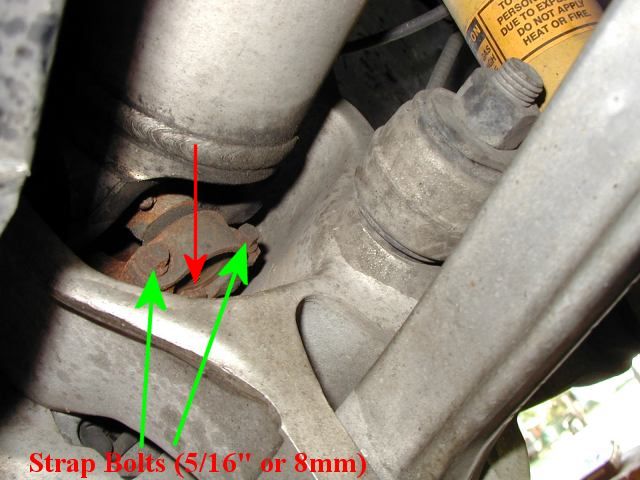

17. Rotate assembly so that two of the 5/16" strap

bolts are accessible on the top of the halfshaft on the differential

end.

You should be able to see them like this. There is lots of WD-40 on

them right now that I sprayed on right after taking the wheels off.

18. Remove two 5/16" strap bolts from differential

side of halfshaft. Use WD-40

liberally.

19. Rotate assembly 180 degrees.

20.

Remove the last two 5/16" strap bolts. Use WD-40

liberally.

Now it is time to remove the wheel side

ones. These will need WD-40 also.

21. Remove two 5/16" strap bolts from wheel side of

halfshaft. Use WD-40

liberally.

22. Rotate assembly 180 degrees.

23.

Remove the last two 5/16" strap bolts. Use WD-40

liberally.

24. Pull wheel knuckle away from the car to

drop halfshaft out. You may have to get a screwdriver

or other prying device in between the universal joints and mounting surface to

help pry the halfshaft out as they can be stuck in

place.

Before you

do anything, this may be a good point to take a little extra time to make

reassembly much easier. I took the 5/16" strap bolts that came out of the

halfshaft, mounting straps, and leaf spring bolt and cleaned them up on a

wirewheel on my bench grinder. They were coated with years of surface rust and

they went in like a dream comparitively when I reassembled everything.

5/16"

Strap Bolts Uncleaned and Cleaned

Mounting Straps Outside Uncleaned and

Cleaned.

Mounting Straps Inside Uncleaned and Cleaned.

No picture of leaf spring

bolt.

Universal Joint

Removal

Note: At any

point that you have the halfshaft itself in the vice, use very very little

pressure. Use just enough to keep it in place. The halfshaft itself is hollow

aluminum, and you could easily squish it if not careful. I know this sounds too

easy to break, but it is the design. The halfshaft's design is not made to

withstand squeezing pressures from the outside, only twisting forces of which it

is very very strong at doing.

25. Remove the 2 snap-rings

from the halfshaft end you are working on.

Squeeze the two ends as seen

in the picture together, and slide a flathead screwdriver under it and pop it

out.

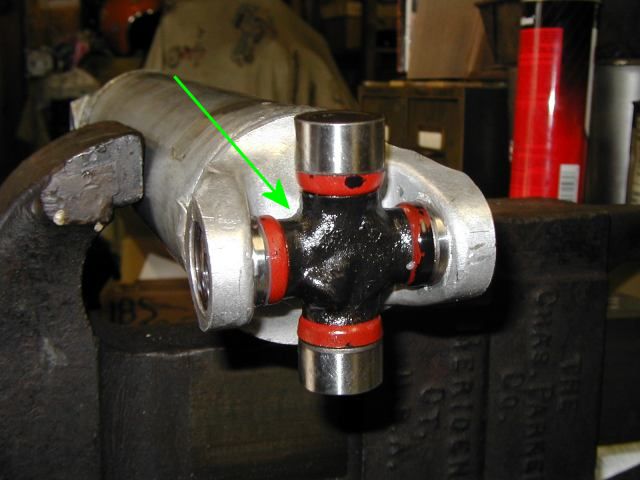

26. Find two sockets. One must be slightly smaller

than the outter diameter of the u-joint (I used 18mm I think), and one slightly

larger than the outter diameter of the u-joint (I think I used 1.5"). See the

picture for what I mean.

Smaller Socket

Larger Socket

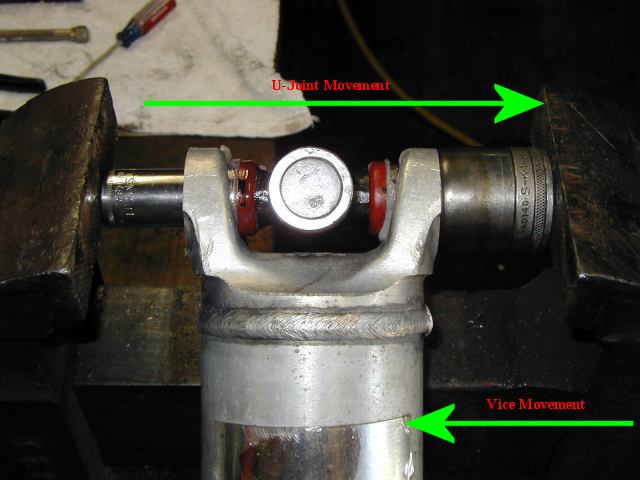

27. Setup the u-joint and sockets in a vice as seen

below.

Small socket on the outside of the vice lined up with u-joint,

large socket on the inside of the vice lined up with u-joint.

28. Now press the vice inward which will also press

one end of the u-joint into the large socket.

29. Once the u-joint has been pressed over as far as

possible, remove the setup from the vice and pull off the cap from the large

socket end with your hands.

30. You should be able to now pull the rest of the

u-joint out of the halfshaft easily.

At

this point I took the time to clean the halfshaft thouroughly. I cleaned all

grime, gook, and whatever else off of it with a bath in kerosene, and then

clothed it down and hit it with some compressed air to fully dry it. You could

easily use something like brake cleaner, or anything else that you know works

good at breaking down grease.

Universal Joint

Installation

31. Press the halfshaft into the vice. See not

about being gentle above.

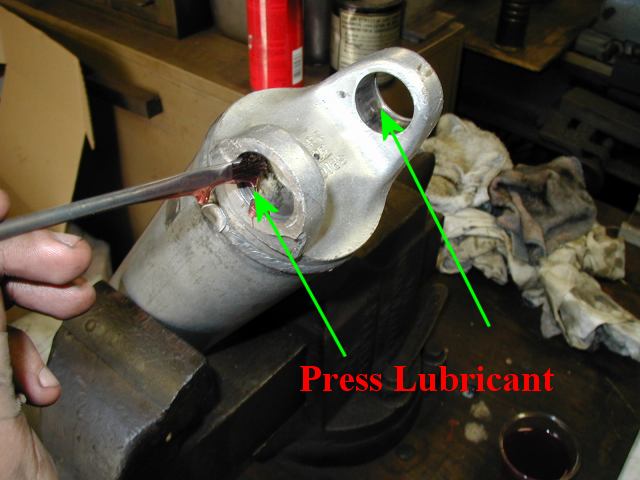

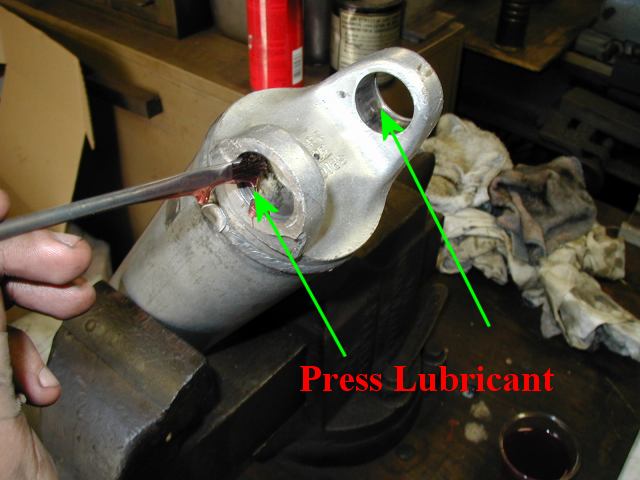

33. Lubricate the innerside of the halfshaft loops

with some sort of press libricant.

Coat as seen with lubricant, you don't

need much as excess will just be pressed out anyways. Even something like motor

oil would probably work here.

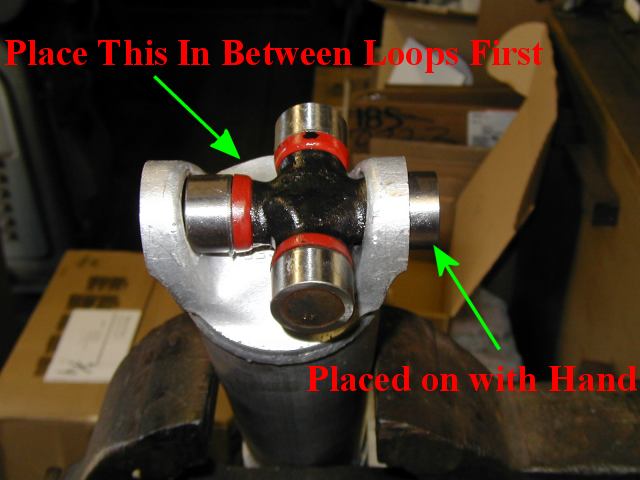

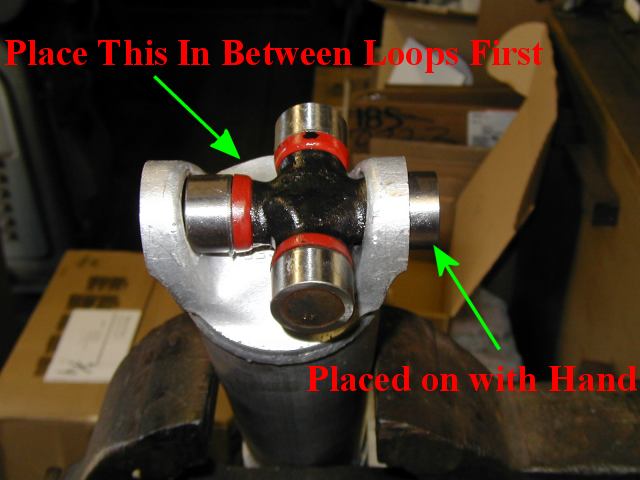

34. Set the new u-joint in place exactly as the old

one was (with one cap off) before you removed it.

35. Install one snapring on

the loop of the halfshaft on the outside of the vice.

36. Place the cap on by

hand and press it on as far as you can gently making sure all is lined

up.

Setup the new u-joint to be installed.

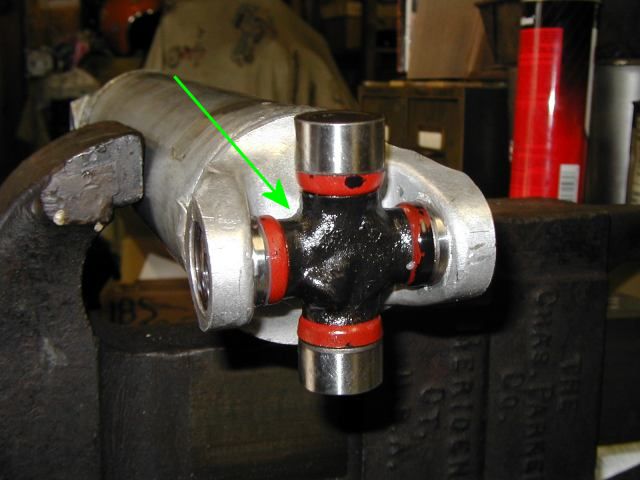

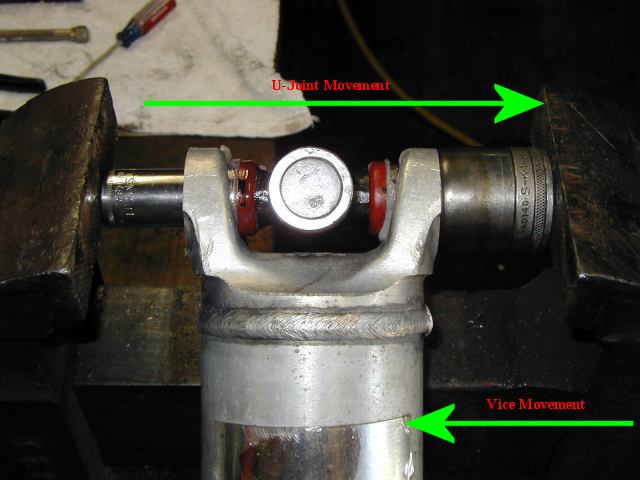

37. Setup the u-joint and sockets in the opposite

manner as when you removed it. Larger socket on the outside loop where the

installed snapring is, and small socket on the inside.

Setup as seen

here, so that when the vice is pressed in, the u-joint will be moved in the

opposite direction pushing it into the halfshaft. In this shot you can see the

white grease from inside the new u-joint that has pressed out during

installation. That is fine.

38. Press the new u-joint in smoothly until you can

feel it come up against the installed snapring. The pressure will increase, this

is how you can tell.

39. Install the snapring on the opposite side

now.

The u-joint may be a little tough to turn as pressing it in loads up

everything to the side that had the large socket on it during install. What I do

is take something like a chisel with a very blunt end on it, and whack it with a

hammer where the green arrow is pointed. You want to whack it

towards the side you put the cap on by hand with. You don't

need much, be very gentle, just a slight tap should work. You should notice that

the u-joint moves much more freely after doing this as the load will be

distributed throughout both sides now evently.

So here is the halfshaft all clean and ready to go

in.

Installation

Installation

is basically the exact same as removal, just in the opposite direction. There

are a few things to consider when reinstalling.

A1. Remember to line up

the Camber Bolt with the score marks when you reinstall it.

A2. Remember to

install the leaf-spring nut so that the same amount of threads are

showing.

A3. Remember to use new cotter-pins where you removed the other

two.

A4. Remember to use some locktite on the 5/16" strap bolts upon

reinstallation.

A5. Remember to make sure the u-joints are on the inside of

the little blocks that hold it in place side to side when it goes back in. They

are hard to see, but can be seen here in this picture at the end of the red

arrow.

All Done

Look any better?

:-)

It might be smart to check the strap bolts after a

couple hundred miles of driving to make sure they are still torqued down nicely.